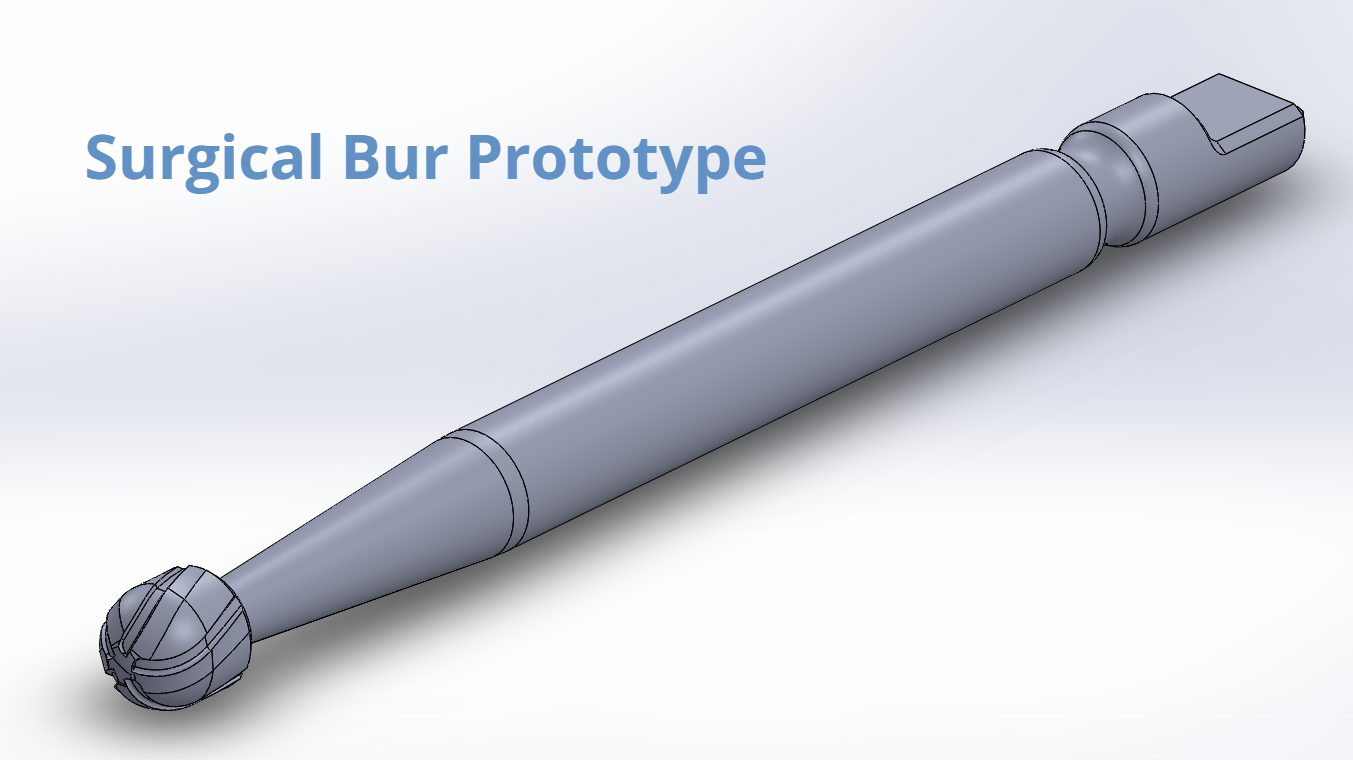

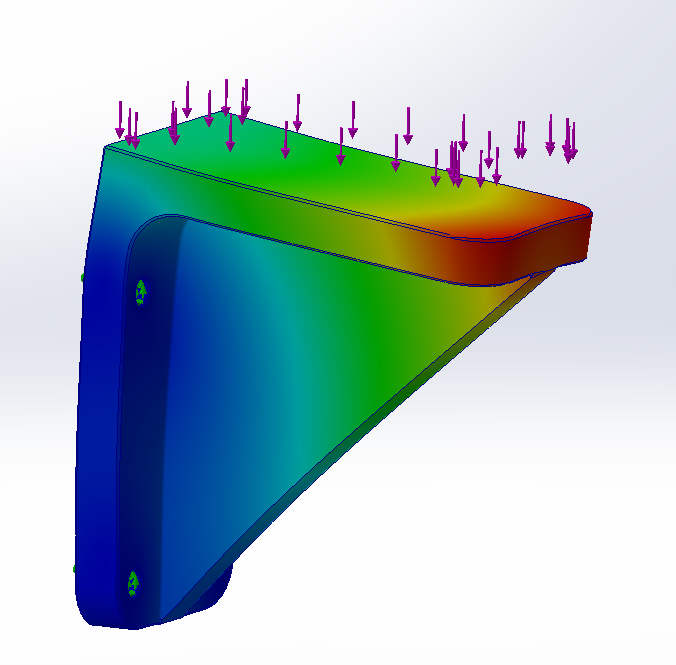

PDC offers wide ranging CAD experience to design and develop fixtures, prototypes and solutions to any problems you need solving.

Every solution, prototype or fixture designed by PDC comes with detailed engineering drawings as standard in accordance with good GD&T practices.

PDC has extensive CNC experience and designs all fixtures, prototypes and solutions to be as manufacturable as possible using readily available technology. This reduces leadtimes and gets you results faster.

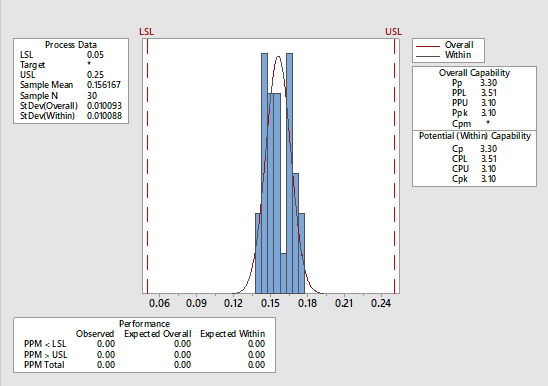

All our fixturing comes with qualification documentation detailing that the fixture has been machined within tolerance and functions as intended.

PDC also offers a 3D printing service to our customers. Customers can chose to get their designs 3D printed for trial purposes. PDC may chose to do this on complex fixturing and prototypes before CNC machining in your chosen material, this is to ensure a everything fits as intended and that no issue arise.